Condition:

New

Range of Spindle Speed(r.p.m):

1 - 24000 rpm

Positioning Accuracy (mm):

0.01 mm

No. of Spindles:

Single

Working Table Size(mm):

1300×2500

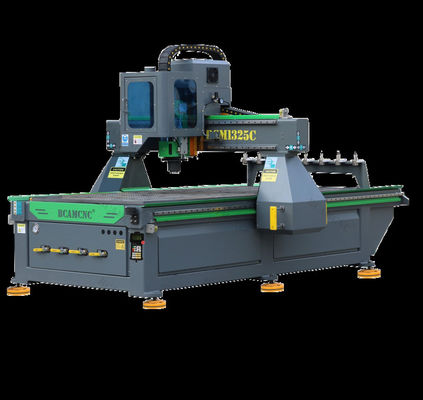

Machine Type:

CNC Router

Travel (X Axis)(mm):

1300 mm

Travel (Y Axis)(mm):

2500 mm

Repeatability (X/Y/Z) (mm):

0.01 mm

Spindle Motor Power(kW):

3.0KW

CNC or Not:

CNC

Voltage:

380V/50HZ

Dimension(L*W*H):

1300*2500*200mm

Weight (KG):

1200

Control System Brand:

NC Studio

Warranty:

24 Months

Key Selling Points:

High Productivity

Applicable Industries:

Manufacturing Plant, Construction works , Advertising Company

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 year

Core Components:

Bearing, Motor, Gear, Gearbox

After-sales Service Provided:

Engineers available to service machinery overseas

Application:

Wood Working

Working area:

1300*2500*200 Mm

Spindle:

China JST 3.0 kw water cooling spindle

Control system:

Weihong 5.449 control system

Motor:

stepper motor

Rail guide:

Taiwan Hiwin

Spindle power:

3.0kw

Transmission:

x,y rail zaixs Taiwan TBI ball screw

Software:

Ucancam / ArtCam/TYPE3

Local Service Location:

Canada, Turkey, United Kingdom, United States, Brazil, Saudi Arabia, Pakistan, Argentina, Chile

After Warranty Service:

Video technical support, Online support, Spare parts

Showroom Location:

United Kingdom, United States, Brazil, Peru, Mexico, Argentina

Zertifizierung:

CE ISO

Marketing Type:

New product 2021

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!